Packaging Automation Tendencies for Cosmetics and Magnificence Care

October 2022’s PACK EXPO Worldwide in Chicago was the primary main PMMI tradeshow that I’ve visited for the reason that COVID-19 pandemic. Because it had been some time, I used to be intrigued to see what can be new for the cosmetics and sweetness care {industry}, particularly contemplating the inaccessibility of factories as a result of pandemic, the scarcity of technical folks, and rising labor prices. Properly, after many miles of strolling the present flooring, numerous observations, and much more questions requested, it was clear that the main target of the present was could possibly be distilled into three important themes: packaging materials sustainability, automation, and the digitization of our world.

Many of the sustainability reveals and talks on the present had been associated to meals and high-volume client merchandise. So whereas sustainability has been a significant theme for cosmetics and sweetness care manufacturers as properly, that’s too huge of a topic for this text. Therefore, I’ll give attention to automation and tools, together with the intensive use of the digitalization of “every thing” and the intensive use of the Web to speak and resolve tools points.

Good automation by way of linear motor monitor programs

New and extra built-in sensible automation options and digitalized machine and plant processes had been launched by plenty of generic automation suppliers.

My private impression is that three firms cleared the path: Beckhoff, ABB’s B&R, and Schneider Electric.

The keys to sensible automation, because it replaces arduous automation, are the linear motor tracks transferring magnetic carriers—typically known as shuttles—together with robots, cobots, and built-in management programs. These sensible bundle holders transport the workpieces individually and at excessive precision by a machine, and with out being sure to inflexible timing (on demand). By now, many automation homes—like Schubert, Syntegon Technology, Groninger, PKB, and Weckerle, to call a couple of—have integrated programs just like the eXtended Transport System (XTS) from Beckhoff, or the ACOPOStrak and SuperTrak from B&R, into their reseptive beauty and sweetness care traces. The benefits of such programs are manyfold. They understand increased working speeds, precision braking and acceleration, and particular person product motion is managed independently of different merchandise, all whereas obviating the necessity for buffer zones. These benefits are key in preserving the very best product aesthetics, very impoirtant for cosmetics and sweetness care, as they eleiminate tough dealing with and speak to between bundle parts. Because of their modular design, new and current programs are simple to scale and rearrange, thus minimizing new funding.  Beckhoff displayed dazzling motion of the carriers on the XPlanar desk.

Beckhoff displayed dazzling motion of the carriers on the XPlanar desk.

The latest improvements I noticed on the present had been the programs that makes use of levitating 2D product transport, with as much as six levels of freedom, known as XPlanar system from Beckhoff, or ACOPOS 6D from B&R. The expertise is predicated on the precept of magnetic levitation: Shuttles with built-in everlasting magnets float over the floor of electromagnetic motor segments. They will transfer freely in two-dimensional house, rotate and tilt alongside three axes, and supply exact management over the peak of levitation. Altogether, that provides them six levels of movement management freedom. Grime attributable to mechanical abrasion, as happens on conveyor belts and chains, is actually eradicated. This prevents soiling and contamination of delicate merchandise and reduces cleansing prices.

I can’t wait to see the subsequent compact meeting line made with this new levitating transport expertise.

Cobots substitute guide labor

The pattern of changing guide labor with cobots was very evident at PACK EXPO Worldwide. To refresh the reader’s reminiscence, the time period cobot refers to Collaborative Robots: robotic arms which have pressure-sensitive sensors enabling them to work alongside folks, whereas eradicating the necessity for costly industrial guards and security scanners. These cobots, on account of their “manipulative” motions mimicking people, at the moment are automating the duties of field/ case forming, case packing and palletizing—if excessive velocity will not be required.

Flexline Automation exhibited an integration its BoxEZ guide case former of Universal Robots cobot. The corporate additionally exhibited one other cell with a further cobot to automate the collation and insertion of the first merchandise into the shaped field and pushing the case by case nearer/taper.

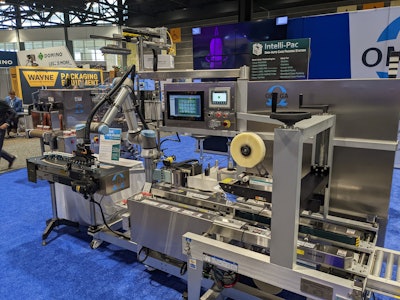

Omega Design Corporation exhibited its Cobot Pack Help for the Intelli-Pac unit, loading a number of containers right into a shaped field. That is monitor and hint case packing, labeling and inspection. Omega claims that the cobot boosts effectivity (sooner operation than guide case packing), considerably reduces human error, frees the operator to give attention to general operation and product high quality, not hand movement.  Omega Design Company exhibited its Cobot Pack Help for the Intelli-Pac unit, loading a number of containers right into a shaped field.

Omega Design Company exhibited its Cobot Pack Help for the Intelli-Pac unit, loading a number of containers right into a shaped field.

And Brooks Automation exhibited its SCARA kind PreciseFlex Collaborative Robots in a palettizing set-up. The benefits of these SCARA cobots are of their simplicity, and in each horizontal and vertical attain envelope.

Late-stage customization places give attention to printing

A key to profitable late-stage-customization is high quality, on-demand printing immediately on secondary and tertiary packaging. This isn’t solely a price financial savings functionality by eliminating labeling or preprinting packing containers; it helps sustainability and eliminates provide chain disruptions for producers and success facilities alike. The power to carry out the printing on the final second earlier than delivery or selecting for cargo affords a singular alternative to customise the printing to particular person shoppers as a advertising device. For instance, wouldn’t you wish to get a field with colourful image of the merchandise inside, or what different merchandise might go properly along with what’s being shipped? Launched at PACK EXPO Las Vegas final yr, the GSI Colorize Inkjet System made its Chicago debut, and impressed cosmetics packaging knowledgeable David Hoenig.

Launched at PACK EXPO Las Vegas final yr, the GSI Colorize Inkjet System made its Chicago debut, and impressed cosmetics packaging knowledgeable David Hoenig.

Inkjet expertise has undergone a fast improvement. A spread of inks, from non-hazardous vegetable oils to UV-cured inks in lots of colours, at the moment are accessible to be utilized on totally different bundle substrates, principally by steady inkjet printing (CIJ) and by the drop-on-demand (DOD) programs. These each use piezoelectric expertise (PIJ) to manage the jetted ink circulation. All suppliers are regularly upgrading their merchandise, enhancing their reliability, maintainability, decision, readability, and compliance with GS1 requirements, together with GS1-128, GTIN-14. The pattern is for the suppliers to combine scanning and scanning software program to confirm that the code is right and readable. Optionally, the suppliers incorporate Business 4.0 parts (and by now some Business 5.0, it appears) comparable to connectivity to manufacturing unit ERP programs, different tools, and thru the cloud to the printer provider for steady tools monitoring. Interacting with Observe and hint software program is one other characteristic changing into well-liked, particularly for the pharma {industry}, however could possibly be used for top worth cosmetics and skincare merchandise to detect and monitor “diversion”. One other improvement is the elevated printing envelops with the usage of giant, excessive decision printing heads.

For instance, Domino launched its all-new Domino Cx350i, a high-resolution DOD case-coding system. The corporate touts the excessive decision, integration of the no upkeep options of the DOD, and what it says is an intuitive management system.

Graphic Solid Inks (GSI) made its PACK EXPO Worldwide Chicago-debut with its multi-color Colorize Inkjet Programs, that includes CMYK+White CIJ with UV cured inks. GSI mixed NoLabel and Colorize Printing heads, with one management system, to be create vivid, high-resolution printing plus bar codes on kraft corrugated. PW has lined this expertise earlier than, however I might see this having an affect particularly on cosmetics and sweetness care.

Diagraph launched its DOD ResMark 5000 high-resolution compact heads with out ink hoses, that includes built-in management for as much as eight heads, patented fast disconnect printer modules for straightforward swap, and localized wi-fi connectivity. Plus, the compamy claims to have the industry-leading ink throw distance as much as 0.5-in.

To not be outdone by inkjet coding, the laser coding market has additionally vastly upgraded itself within the years since I used to be on the final PACK EXPO Worldwide. Totally different UV wave lengths are supplied, in addition to highly effective CO2 choices, so extra substrates, together with metallic, might be clearly marked and skim by scanning {hardware} and software program. The etching envelope have additionally grown considerably.

Videojet, for instance, exhibited 60-Watt CO2 Laser Marking System with an etching envelop of virtually 4 sq ft, and with lifetime of 45,000 hours, it will possibly save numerous ink.

One other key ingredient in late-stage customization is the power to deal with (and print or code) main packages moderately than having to get them preprinted. That is very useful for brief runs or promotional customization, each frequent in cosmetics and sweetness care. The technological problem is to have flexibility to deal with a variety of codecs on the identical tools, with minimal or simple change overs.

HSAUSA launched the VFS-1000 Vertical Feeding System that takes a singular strategy to the way in which folding cartons, luggage, and pouches are magazined and delivered to a conveyor. Stand-up folding cartons, pouches, and luggage are standing on an edge, picked, and positioned onto a shuttle desk, then pushed on to the downstream conveyor, presumably for printing or labeling. It’s a batch operation, however the replenishment of the blanks might be achieved with out stopping the tools. The VFS-1000 is a part of a household of modules that may be put collectively to routinely deal with, print (or label), examine or reject and stack up completed components.  Sonoco Alloyd has been touting their EnviroSense PaperBlister bundle as a technique to contribute to a model’s sustainability profile.

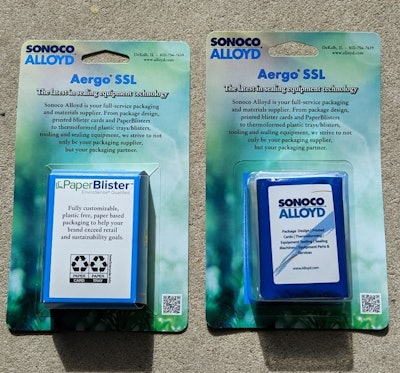

Sonoco Alloyd has been touting their EnviroSense PaperBlister bundle as a technique to contribute to a model’s sustainability profile.

A typical retail cosmetics vector for late-stage-customization is blister packaging. Sonoco Alloyd launched the Aergo line of blister sealing packaging tools. The Aergo line options warmth, fusion, and RF sealing expertise. Plus, it makes use of servo motions moderately than mechical, thus enhancing denesting capabilities, and might be scaled up with extra choices. The Aergo SSL 11 station servo-driven machine on the present had all the required stations to deal with each plastic blister and EnviroSense PaperBliste, and featured Alloyd quick-change warmth seal tooling. Sonoco Alloyd has been touting their EnviroSense PaperBlister bundle as a technique to contribute to a model’s sustainability profile.

Most cosmetics and sweetness care containers are sourced from abroad. To take care of purity contained in the container within the interval between making the container and filling it, some producers opted to have the container delivered to their filling operation already pre-capped. This fashion, no mud or filth can enter the container. To deal with these precaped bottles, the filling tools must take away the caps, put the caps on a shuttle system, fill the open containers, and re-cap/re-torque the containers. Whereas this complicates the fillers, it does have one important operational benefit and one high quality benefit. There isn’t any want for unsramblig tools and sophisticated set-up for changeovers, and there’s no extra bodily dealing with of the caps, additional sustaining the unique aesthetic of the caps with out dealing with harm.

PKB has began to supply this un-capping, to fill, to re-capping characteristic as properly. For example, I noticed a video at PKB sales space of a excessive velocity filler performing the un-capping and re-capping.

Many suppliers touted distant entry for tools troubleshooting, all by the web, and plenty of instances utilizing the sensible telephones because the entry and communication device.

NITA exhibited a variety of its SENTIANT labelers, and the main target in its sales space was all about uptime, seamless distant monitoring, and upkeep entry by way of the web (or cloud). NITA claims that their labelers are the best to keep up on account of 100% License-free, non-proprietary electronics and software program, all synchronized servos (no PLCs, and so forth.), stay tech assist by way of the web, Self-Diagnosing software program system with in-screen components ordering, and built-in preventative upkeep.

Tools improvements for tubes within the cosmetics market

Tubes are a typical bundle format within the cosmetics, physique, and hair care {industry}, typically in a number of sizes and art work ornament. So, how do you make manufacturing extra environment friendly? Straightforward and quick changeovers is one reply.

Citus-Kalix, a part of the COESIA Group, launched its newest high-speed simplex (one filling nozzle) KX1103 EVO tube filler for plastic and metallic, able to producing at 110 tubes/min. The producer calls the machine “the subsequent technology,” primarily as a result of fast changeover. The declare is 10 minutes [of changeover time] to start out a brand new manufacturing run. The tools accomplishes the quick changeover with automated servo-driven changes the place attainable, format set-up information registered in recipe, devoted change components that may be simply swapped (no changes wanted and ideally no instruments), and now increasingly more, step-by-step directions on the HMI.

Tubes for cosmetics and sweetness care have been principally sourced from China. Issues within the provide chain on account of COVID-19 from China created a requirement for brand spanking new tube labeling tools. Pendergraph Machines launched its tube pre-labeler TL-60, which was built-in with to a

Conveyors for cosmetics are additionally advancing

Whereas some tools traits that I noticed on the present are pointing in direction of extra linear servo or magnetic movers/shuttles, conveyors are nonetheless a cornerstone of most packaging traces. And no trendy conveyor system is actually full except it will possibly deal with a number of merchandise with out jams or time-consuming changeovers. So conveyors aren’t going away, and we nonetheless must unscramble parts. Light unscrambling and transporting are key to secure dealing with of beauty merchandise, the place aesthetics are key.

Producers of horizontal movement conveying programs grapple with how one can decrease vertical “rubbing” motion and fixed vibration between components being transported in linear transport chutes. A number of producers displayed a brand new idea of oscillating chutes that didn’t create vertical vibration. A profiled motion backwards and forwards (cam-driven linear movement) “pulls the rug”  A number of producers displayed a brand new idea of oscillating chutes that didn’t create vertical vibration. A profiled motion backwards and forwards (cam-driven linear movement) “pulls the rug” from beneath the parts that wish to proceed transferring ahead as a result of inertia imparted by the ahead motion.

A number of producers displayed a brand new idea of oscillating chutes that didn’t create vertical vibration. A profiled motion backwards and forwards (cam-driven linear movement) “pulls the rug” from beneath the parts that wish to proceed transferring ahead as a result of inertia imparted by the ahead motion.

Extra typically talking, I used to be thrilled to see so many advances exhibited and mentioned at PACK EXPO Worldwide after my lengthy hiatus, and the above are solely the highlights that one traveler down the aisles of PACK EXPO was capable of uncover. It may’t assist however make you marvel what we’ll see subsequent yr in Las Vegas.

Source link